Design

A diligent and comprehensive design process is clearly fundamental to the successful delivery of our works, accordingly we employ a strong team of highly experienced draughtspersons in both our façade and metalwork drawing offices.

Once appointed to a new project, a detailed internal handover process takes place. This is followed by our appointed design personnel reviewing all pertinent information prior to the preparation of our own detailed drawings.

At Dane we recognise the clear benefits to all project stakeholders in ensuring that our design works are fully and accurately completed in a timely manner. We also appreciate the need for, and benefits of, regular dialogue and close collaboration between all other relevant parties including Main Contractor, Architect, Consultants, and interfacing Trade Contractors. This provides all those with a vested interest to be considered and involved as our design works are being progressed to construction status.

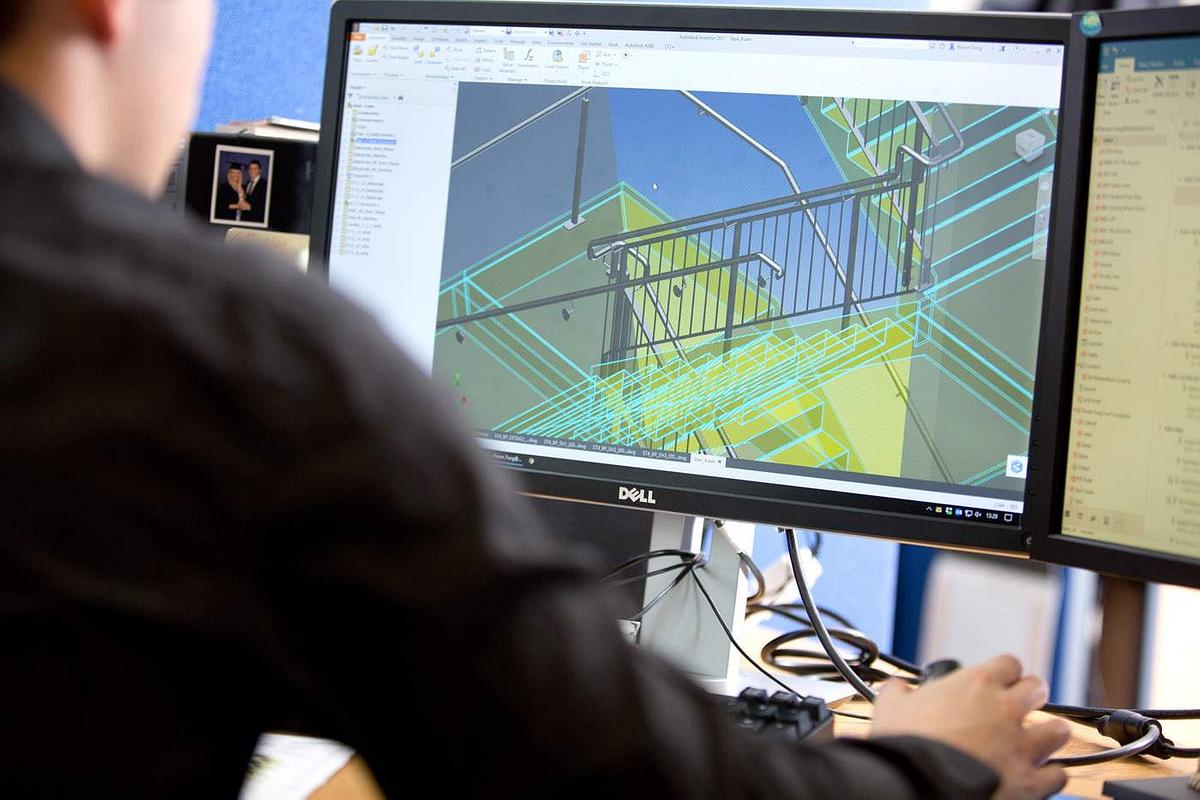

The very significant advancements that have been made in 3D design modelling are fully embraced by Dane. We have, over recent years, made substantial investments in both hardware and software as well as the required staff training programmes.

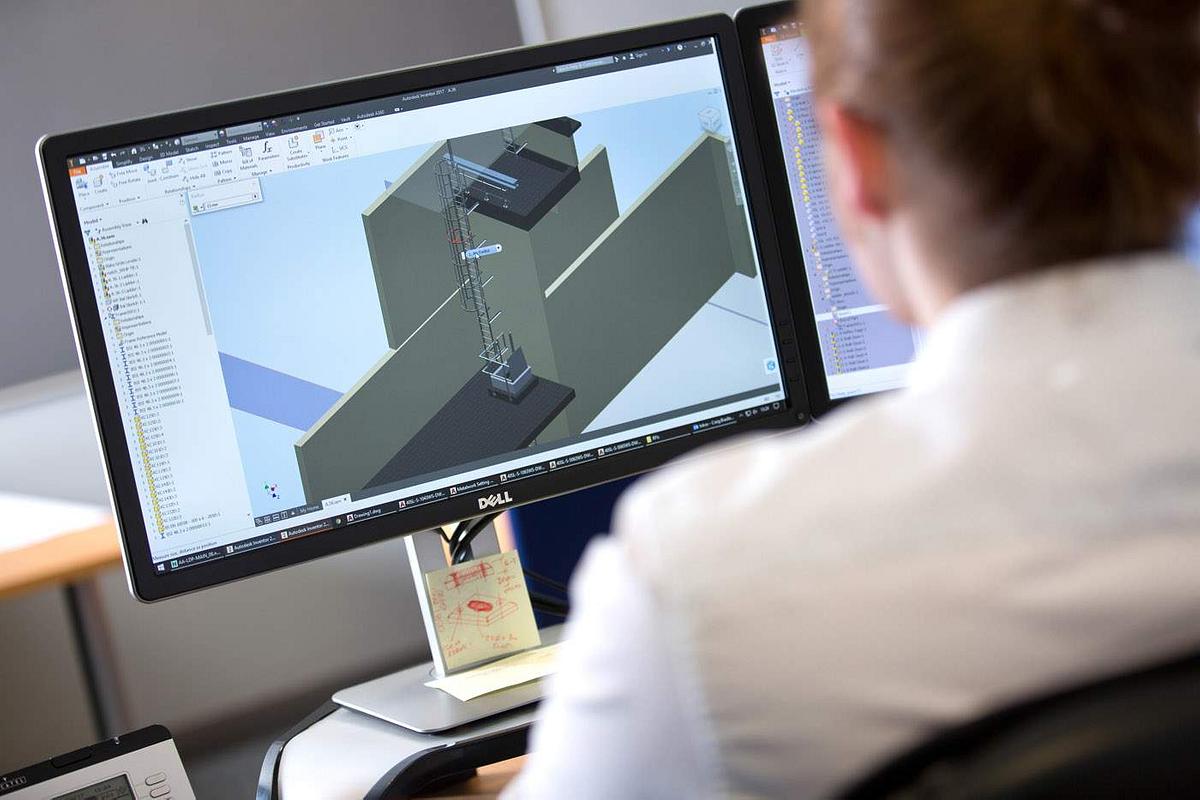

In 2016 BIM Level 2 became a legal requirement for all centrally procured public sector projects. It was apparent from the outset, that this development would impact on our organisation. Significant investment was inevitable, therefore, rather than dealing with BIM as an additional task (i.e. where mandatory), we opted for a fundamental shift in working practices. Tailoring the Dane solution was a sizeable task. Not only do we collaborate with architectural, structural & MEP design stakeholders, we are a bespoke engineering, manufacturing and construction company.

Key to the successful implementation was selecting 3D software packages fit to facilitate our operational needs, utilising those tools across the board (regardless of project specific criteria) and then realising the benefits associated with detailed modelling, meaningful analysis and improved automation throughout the business and supply chain.

This “bottom up” approach has resulted in all procurement, production and installation activities, being driven by parameters extracted from verified models and synchronised with relevant ERP (Enterprise Resource Planning) data. Satisfying BIM requirements from this position is a formality, of course, understanding and adhering to relevant codes of practice is essential in terms of successful handover.

As well as ultimately achieving BIM Level 2, we have improved communication and reduced defects. We will continue to increase productivity by modernising CNC software links and machinery, capitalising on the automated data we now have at our disposal.